Notable Aspects of Our Factories

Seamless automation

SCADA

Controlled manufacturing process that produces consistent output, untouched by human hand.

Chocolate comes in many forms

Wide Range of Bulk SKUs

From poly pouches to buckets to tankers, we tailor delivery to suit varied customers' needs

State-of-the-Art machinery from

5 Countries

Netherlands, Germany, Italy, Switzerland, and India.

Number of Employees

700

Working in 5 manufacturing plants in 2 locations

Production Process

- Ingredient Sourcing & Preparation: DP Chocolates begins with selecting high-quality cocoa and supporting ingredients like sugar, cocoa butter, and milk solids. These are carefully weighed and blended to create a consistent chocolate base.

- Grinding & Refining: The mixture is passed through advanced grinding and refining machines to reduce particle size and create a smooth, uniform texture that defines premium chocolate.

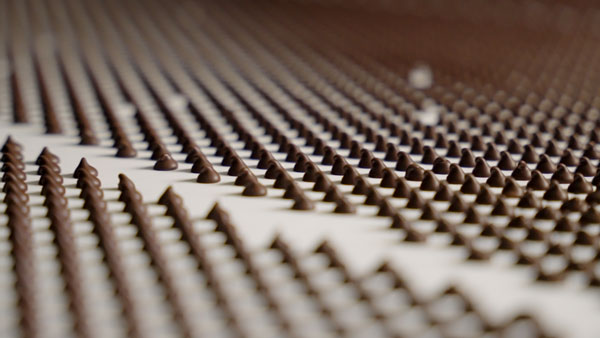

- Molding & Shaping: Once tempered, the chocolate is deposited into precise molds—ranging from bars and buttons to custom shapes. Vibration is used to eliminate air bubbles and ensure even surfaces.

- Cooling & Packaging: Molded chocolate is gradually cooled in controlled environments and then packed using automated systems. Products are sealed to preserve freshness and stored under ideal conditions for delivery.

Infrastructure at DP Chocolates

DP Chocolates employs a highly efficient production setup that begins with temperature-controlled storage to preserve the quality of raw materials, followed by automated feeding and blending units that ensure consistent batch formulation. The chocolate mass is refined using multi-roll refiners that achieve an ultra-fine texture. Conching is carried out using energy-efficient machines equipped with time and temperature controls to enhance flavor development and texture. Advanced tempering machines then regulate heat cycles and crystal formation, ensuring each batch meets desired texture and visual standards. Precision molding lines handle a variety of formats including bars, chips, and slabs. The shaped chocolate is cooled using multi-stage cooling systems with controlled airflow to maintain structural integrity. Packaging is managed through automated wrapping, filling, and sealing machines. Throughout the process, internal quality monitoring with routine sampling ensures production accuracy and flavor consistency.

Commitment to Excellence

DP Chocolates maintains a modern, hygienic, and efficient production environment. Every step—from raw material handling to final packaging—is designed for precision and consistency. With flexible lines, advanced machinery, and skilled professionals, the facility delivers products that meet diverse market demands while staying true to the brand’s promise of chocolate crafted with care and expertise. The company’s strengths lie in its use of state-of-the-art technology, strict quality protocols, and continuous employee training. Every batch undergoes rigorous testing for taste and texture, supported by robust traceability systems that ensure accountability at every stage. This combination of operational excellence and passion for chocolate enables DP Chocolates to consistently exceed expectations.

Understanding the Process in Depth

Our production is divided into two distinct processes

Cocoa Bean Processing

The Cocoa Production Process focuses on transforming raw cocoa beans into high-quality cocoa products like cocoa nibs, cocoa mass, cocoa butter, and cocoa powder through a series of precise quality checks and refining steps.

Watch our cocoabean processing

Bulk Chocolate Manufacturing

The Chocolate manufacturing process uses the refined cocoa ingredients and blends them with other components to create our signature chocolate, ensuring a consistent, rich flavor and texture. Both processes work seamlessly together, each with its own set of stages, allowing us to deliver exceptional products tailored to diverse needs

Watch our chocolatemanufacturing process

Certifications